Services

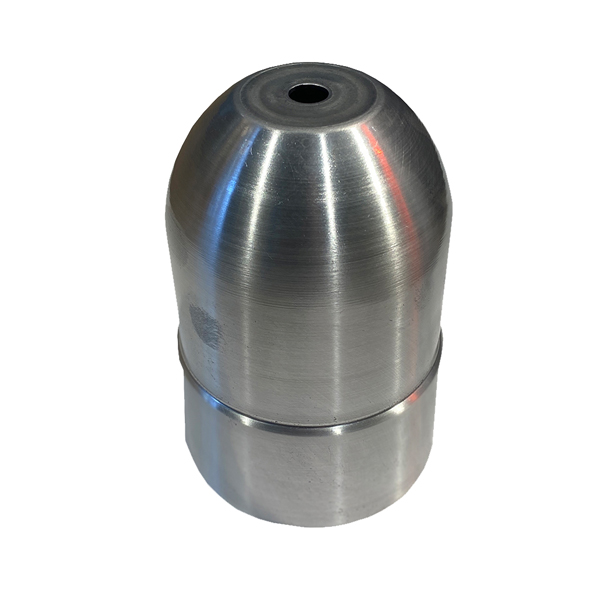

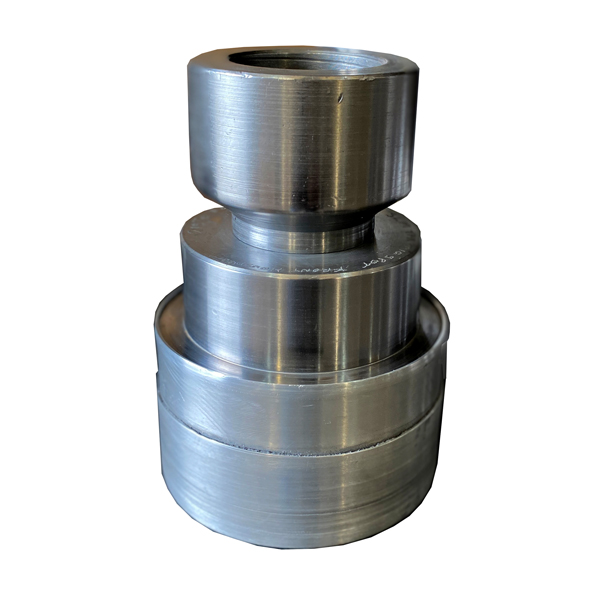

Metal Spinning

For over four decades our metal spinning experts have been meeting the needs of our customers, both locally and nationwide. Based in Monmouthshire, South Wales, our engineers are available to discuss all your metal spinning, profiling and fabricating requirements.

From turning your hand drawn ideas into professional CAD drawings, our highly skilled team will work with you from conception to completion to ensure your requirements are executed to a high standard.

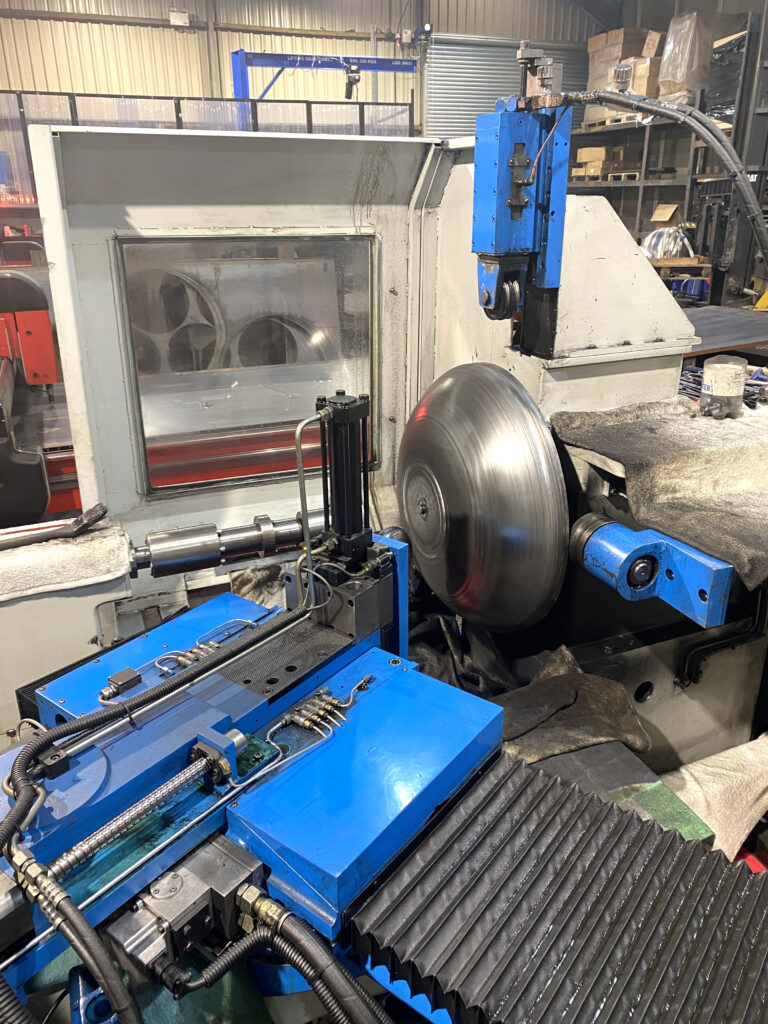

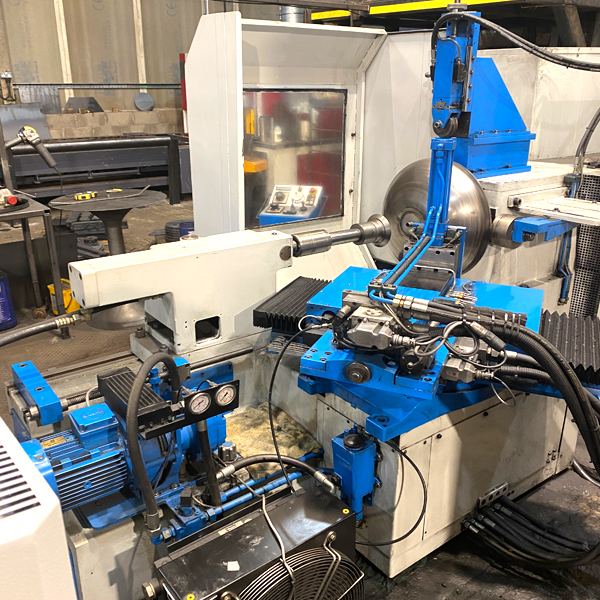

Metal spinning is the process of flow forming metal over a forming tool at high speed. Our state-of-the-art PNC/CNC spinning lathes allow us to spin components up to a thickness of 6mm and a diameter of 1100mm using a variety of metals, including Stainless Steel, Copper, Brass, Aluminium and Zintec. See our spinning machines in action below.

Leifeld CNC Spinning Lathe PNC 75

Maximum blank 700mm.

6mm Steel – 4mm S/Steel

Spinning Lathe’s PNC 500 x 2

Maximum blank diameter 1100mm.

4mm Steel – 3mm S/Steel

Leifeld Spinning Lathe PNC 400

Maximum blank 850mm

8mm Steel – 6mm S/Steel

Spinning Lathe’s PNC 500

Maximum blank diameter 1100mm.

4mm Steel – 3mm S/Steel

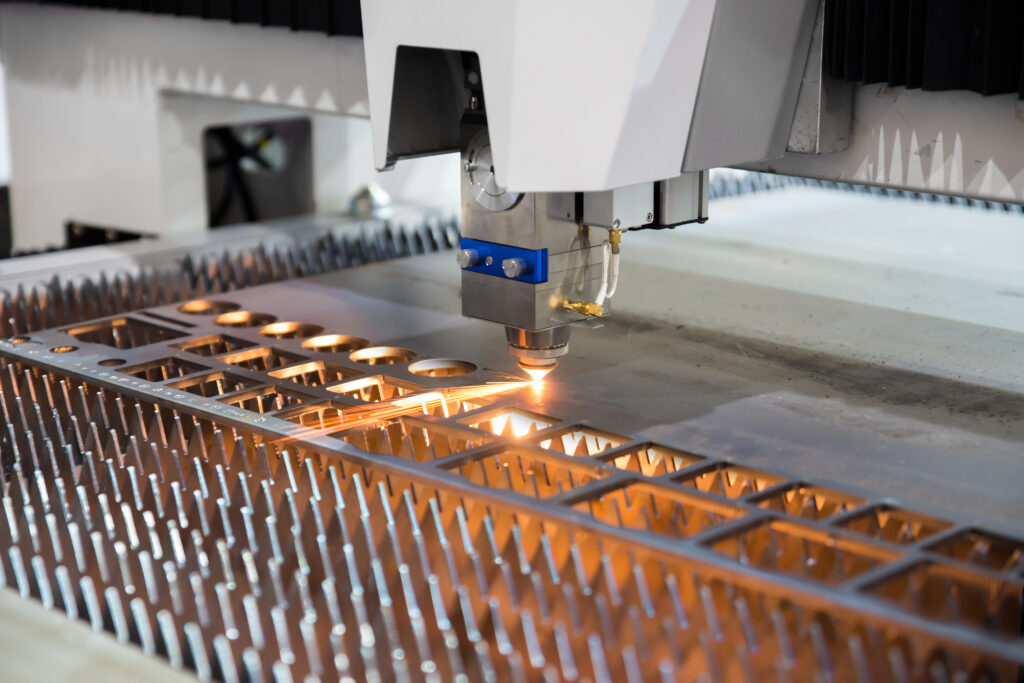

Sheet Metal Profiling

Using CNC technology, our Rushworth 3kW Fibre Laser cutting machine allows cutting accuracy to the finest details in sheet, plate and box section using a variety of materials, including Stainless steel max 10mm – Mild Steel max 15mm – Aluminium 8mm. No job too big or too small. Free local delivery (15 miles). Two working day turnaround.

Outsource Your Sheet Metal Profiling

Rushworth 3kW Fibre Laser – CNC technology

Mild Steel – Max 18mm

Stainless Steel 6mm

Aluminium 5mm